Quartz single crystal wafers cut in a certain direction will generate an electric field or electric charge proportional to the stress when subjected to mechanical stress. This phenomenon is called the positive piezoelectric effect. Conversely, when the quartz crystal is subjected to an electric field, a strain proportional to the electric field will be generated. This phenomenon is called an inverse piezoelectric effect. The positive and negative effects are collectively referred to as the piezoelectric effect. Quartz single crystal not only has a piezoelectric effect but also has excellent mechanical, electrical, and temperature characteristics. The resonators, oscillators, and filters designed and manufactured by it have outstanding advantages in frequency stabilization and frequency selection.

OST Photonics offers a variety of sizes and thicknesses of SAW&optical grade Quartz single crystal wafers, with wafer diameters ranging from 1 inch to 8 inches, the thickness can be customized according to your requirements (generally above 0.05 mm). The orientations can be X/Y/Z/AT32/AT33/AT36/BT/ST42.75 etc. In addition, high-quality quartz blanks (including left-handed quartz) are also available. Contact OST Photonics to learn more about the price of single crystal quartz wafers and piezoelectric quartz single crystals.

Fused silica (fused quartz) and quartz single crystal are two different materials.

Firstly, they are produced differently. Fused quartz is produced by processing silica into lumps or tubes at high temperatures, while quartz single crystals need to be grown under specific conditions.

Secondly, their physical properties also differ. Due to the existence of small defects and impurities in the preparation process, fused quartz exhibits more optical scattering, absorption, and emission phenomena than perfect quartz single crystals do.

Additionally, in terms of mechanical strength, its internal structure is more complex and contains a large number of voids and cracks among other factors, resulting in relatively low compression capacity for fused quartz.

Finally, there are differences in their applications as well. Thanks to its excellent transparency, high temperature resistance, and electrical insulation properties; fused quartz finds wide usage in the semiconductor industry, solar panel manufacturing sector as well as optical instruments field. On the other hand, quartz single crystals find primary application areas within scientific experiments domain along with precision instruments sector as well as jewelry industry.

Quartz single crystal is a kind of material with wide application. It has excellent physical and chemical properties, so it has been widely used in many fields.

First, in the electronics industry, quartz single crystals are widely used to manufacture high-precision oscillators and resonators. These devices can steadily produce signals of specific frequencies, making them important in fields such as communications, computers, and radio.

Secondly, in the field of optics, quartz single crystals also play an important role. Because of its high transparency and resistance to radiation damage, it is often used in the manufacture of optical fibers, lasers, and various optical instruments. At the same time, the quartz single crystal can also adjust the speed and direction of light propagation by controlling its structure, so as to achieve accurate control of the light signal.

In addition, in scientific experiments, quartz single crystals are often used. Because of its good stability and easy to be affected by external interference, it has become an indispensable part of many experimental devices. For example, using quartz single crystals as a sample holder in X-ray diffraction experiments can obtain more accurate and clear diffraction patterns.

Finally, it is worth mentioning that in the watch industry, quartz single crystals also play a crucial role. Using the characteristics of its piezoelectric effect, quartz single crystals can convert mechanical energy into electrical energy and maintain a very stable and accurate vibration frequency. This makes the watches, alarm clocks and other time measuring devices we use every day have excellent accuracy.

In short, "quartz single crystal" has a wide range of applications and plays an important role in many fields. With the continuous advancement of scientific and technological progress and innovation, "quartz single crystal" will continue to show greater potential and value, and bring more surprises and convenience to mankind.

Quartz single crystal is a kind of material with many special properties and wide application. First, quartz single crystals have extremely high hardness and wear resistance, making them one of the indispensable materials in the manufacture of high-precision instruments, optical components and electronic devices. Second, quartz single crystal has excellent optical transparency, can transmit light in the ultraviolet to infrared band range, and almost no absorption loss, so it is widely used in laser technology, optical communication, photography lenses and other fields.

In addition, quartz single crystals also show good mechanical and chemical stability. It remains structurally intact at high temperatures and is not easy to deform, making it one of the necessary materials for the manufacture of parts and devices used in high-temperature working environments. At the same time, it can also maintain good stability in common corrosive media such as acid and alkali, extending equipment life and improving work efficiency.

In addition, quartz single crystals also have excellent electrical properties. It is a very good insulator and has little response to electric fields; At the same time, it can also exhibit piezoelectric effect and transparent conductive characteristics in some cases. These characteristics make quartz single crystals play an important role in micromechanical systems (MEMS), acoustic filters, sensors and other fields.

In summary, the main characteristics of "quartz single crystal" include: extremely high hardness and wear resistance, excellent optical transparency, good mechanical and chemical stability, and excellent electrical properties. These outstanding characteristics give the material a wide range of important application value, and play an irreplaceable role in the field of science and technology.

SAW & Optical Grade Quartz Single Crystal Wafers of OST Photonics

|

|

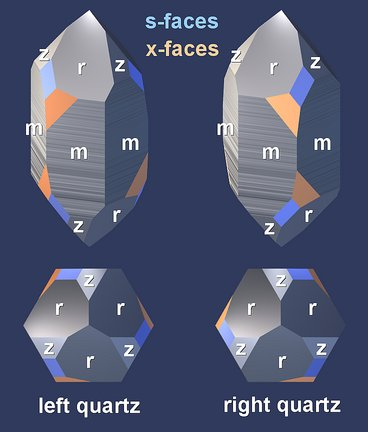

The rule of thumb to determine the handedness is:

If an x- or s-face is present at the left side of an r-face, the quartz is called left-handed (or left quartz, for short).

If an x- or s-face is present at the right side of an r-face, the quartz is called right-handed (or right quartz, for short).

The figure shows the s-faces (tinted blue) and x-faces (tinted orange) on both left- and right-handed quartzes and their relative position to the r-, z-, and m-faces.

Left and right quartz are mirror images of each other, but lack mirror symmetry themselves.

Double-terminated crystals with all s- and x-faces on them like those on the idealized renderings are extremely rare. Most crystals don't show s- and x-faces, and those that do often have only one or two of them, and either x- or s-faces, but rarely both of them.

The cutting of crystal axis by quartz wafer is called the cutting mode of quartz wafer. Due to the anisotropy of quartz crystal, the electrical and thermal properties of different cut quartz chips are different because of their elastic properties, piezoelectric properties and temperature properties.

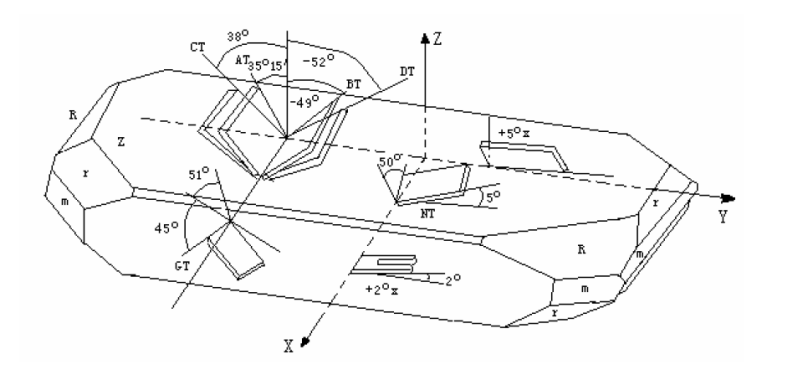

The following figure shows the positions of various cutting patterns:

(1) the cut symbol indicates:

There are two ways to express the cut symbol of quartz single crystal, one is the symbol representation stipulated by ire standard, the other is the customary symbol representation peculiar to quartz single crystal. The cut symbols specified by ire are represented by a set of letters (xyzlwt) and angles, the thickness and length of the wafer along the original direction of the coordinate axis are represented by the sequence of three letters in XYZ, the direction of rotation is represented by T (thickness), l (length) and w (width), and the positive sign of the angle is represented by anticlockwise rotation and the negative sign is represented by clockwise rotation.

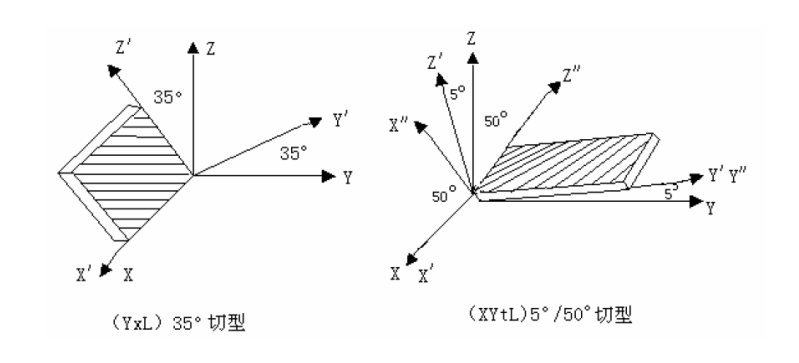

Example: (YXL) 35 ° original wafer angle: Y direction

Original wafer length: X direction

Rotate 35 ° anticlockwise around the length direction (x axis) to get the cutting direction of the wafer, (xytl) 5 ° / - 50 ° thickness t (x axis) 5 ° anticlockwise, and then rotate 50 ° clockwise around the length L (Y axis), which is the cutting direction of the quartz wafer.

The customary symbols of quartz single crystal are mostly expressed in two English capital letters. For example, the customary symbols of (YXL) 35 ° cut type are expressed in at, and (xytl) 5 ° / - 50 ° are expressed in NT.

(2) common quartz single crystal cutting type:

| Cutting Type (Orientation) | Vibration Mode | Frequency Range | Shape | |

| (XYt) 0°~5° | X0°~5° | thickness bending | 2~50KHz | rod |

| (XYt) -18°30′ | X-18°30′ | length extension | 50~500KHz | long sheet |

| (XYtl) 5°/-50° | NT | plane bending | 16~100KHz | long sheet |

| (YXl) 35° | AT | thickness shear | 500KHz~350MHz | disc (rectangular sheet) |

| (YXl) -49° | BT | thickness shear | 3MHz~75MHz | disc (rectangular sheet) |

| (YXl) 37°~38° | CT | plane shear | 200KHz~1000KHz | square sheet (rectangular sheet) |

| (YXl) -52°~-53° | CT | plane shear | 100KHz~600KHz | square sheet (rectangular sheet) |