Application of SAW Grade Quartz Single Crystal Wafers

Resonators and sensors in 5G communications

SAW devices in radar systems and satellite communications

Oscillators and sensors in navigation systems

Temperature compensate crystal oscillator (TCXO)

Oven controlled crystal oscillator (OCXO)

Advantages of SAW Grade Quartz Single Crystal Wafers

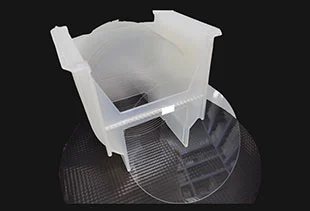

Ability of SAW Grade Quartz Single Crystal Wafers

Orientations: X/Y/Z/AT32/AT33/AT36/BT/ST42.75 etc.

Diameter: 3”, 4”, 6”, 8”

Thickness: 0.25mm, 0.35 mm, 0.5 mm, 1.0 mm etc.

Available items: crystal wafers, blanks and customized optics

Product Parameters of SAW Grade Quartz Single Crystal Wafers

Material | Quartz Crystal |

Cutting Angle | X/Y/Z/AT32/AT33/AT36/BT/ST42.75 etc |

Diameter | 3”(76.2mm) | 4” (100mm) | 6"(150mm) | 8"(200mm) |

Diameter Tolerance(±) | ≤0.20 mm |

Thickness | ≥0.08mm | ≥0.10mm | ≥0.20mm | ≥0.35mm |

Primary Flat | 22mm | 32mm | 42.5mm | 57.5mm |

LTV (5mmx5mm) | <1µm |

TTV | <3µm |

Bow | -30<bow<30 |

Warp | <40µm |

PLTV(<0.5um) | ≥95%(5mm*5mm) with 2mm edge excluded |

Orientation Flat | According to our standards or your requests |

Surface Type | Single side polished(SSP)/double sides polished(DSP) |

Polished side Ra | <0.5nm |

Back Side Criteria | General is 0.2-0.5µm or as customized |

Edge Criteria | Compliant with SEMI M1.2 Standard/refer to IEC62276 |

Material Property | ECD | Better than grade 4 |

Inclusion | Better than grade II |

Q-Value | Better than grade C |

Wafer Surface Criteria | Particles φ>0.3 µm | <= 30 |

Scratch , Chipping | None |

Defect | No edge cracks, scratches, saw marks, stains |

Packaging | Qty/Wafer box | 25pcs per box |

Product Parameters of SAW Grade Quartz Single Crystal Blanks

Material | Quartz Blanks |

Materials | Both Pure Z and Y Bar available |

Synthetic Q-Value | Min 1.8x10^6, 2.4x10^6 to 3.0x10^6 IEC |

Etch Channel Density | Max 10/cm2, Max 30/cm2, Max 100/cm2, Max 100/cm2, Max 300/cm2; Swept |

Inclusions Density | Ia, Ib, I, II, III |

Cut Type | AT, BT, CT, DT, GT, NT, FC, SC, IT etc |

Angle Tolerance(±) | Theta Angle: ±5″, ±10″, ±15″, ±30″, ±1′, ±2′ etc |

Phi Angle:±5′, ±10′, ±15′, ±30′ etc |

Diameter For Round Blank | From 3.0mm to 50.80mm (with flat) |

Size For Square Blank | 1.6x1.6mm ~ 38x38mm |

Size For SMD Blank | 1.2x2.4mm Above at Customer option |

Diameter/Size Tolerance(±) | ±0.01 mm |

Frequency | 1 Mhz up to 54Mhz for AT-Cut Fundamental; Upto 70Mhz By Etching |

Flat | As request the flat shall be perpendicular to X axis within ±10 deg |

Surface Finishing | #1000(9u); #2000(7u); #3000(5u); #4000(3u) (Sic); Polished(Cerium oxide)and & etched Std |

Overtone | Fundamental; Third Overtone (3rd); Fifth Overtone (5th) |

Contouring (Diopter) | Plano-Convex: 0.5 Diopter ~ 10 Diopter Bi-Convex: 10 Diopter ~ 15 Diopter |

Properties of SAW Grade Quartz Single Crystal Wafers

Density, g/cm3 | 2.65 |

Melting point, °C | 1467 |

Thermal conductivity, W/(m x K) (T = 25°C) | 10.7 (parallel to axis Z) 6.2 (perpendicular to axis Z) |

Thermal coefficient of linear expansion at temperature range 0-25°Ñ, °C-1 | 7.1 õ 10-6 (parallel to axis Z) |

13.2 õ 10-6 (perpendicular to axis Z) |

Hardness (Mohs) | 7 |

Specific heat capacity, J/(kg x K) (T = 25°C) | 710 |

Dielectric constant at 30 MHz | 4.34 (parallel to axis Z) 4.27 (perpendicular to axis Z) |

Young's modulus (E), GPa | 97.2 (parallel to axis Z) 76.5 (perpendicular to axis Z) |

Shear modulus (G), GPa | 31.14 |

Bulk modulus (K), GPa | 36.4 |

Chemical stability | insoluble in water |

Elastic coefficients | C11=87 C12=7 C44=58 C13=13 C14=18 C33=106 |

Synthetic Crystal Quartz Refractive Index VS Wavelength

l, mm | n0 | ne | l, mm | n0 | ne | l, mm | n0 | ne |

0.185 | 1.676 | 1.69 | 0.243 | 1.605 | 1.617 | 0.589 | 1.544 | 1.553 |

0.194 | 1.66 | 1.673 | 0.263 | 1.593 | 1.604 | 1.083 | 1.534 | 1.543 |

0.204 | 1.643 | 1.656 | 0.291 | 1.581 | 1.591 | 1.8 | 1.524 | 1.532 |

0.219 | 1.625 | 1.637 | 0.34 | 1.567 | 1.577 | 2.5 | 1.512 | 1.52 |

0.231 | 1.614 | 1.626 | 0.405 | 1.557 | 1.567 | 3 | 1.5 | 1.507 |

Quality Evaluation of Synthetic Quartz Crystal

a) The amount of crystal defect and impurity in synthetic quartz crystal depends on growth rate, mineralizer and raw material. The growth rate affects greatly to the important properties such as infra-red absorption coefficient α, which correlates to Q value, and frequency –temperature characteristics. The larger growth rate causes increase in α, decrease in Q value, and dispersion in frequency-temperature characteristics.

b) The quality index of synthetic quartz crystal was originally a Q value, and a 5 MHz quartz crystal unit operated in 5th overtone mode was used to obtain the Q value. But it required laborious work to fabricate the 5 MHz crystal unit, so the index had been changed to the coefficient α instead of the Q value.

Standard Specification for Synthetic Quartz Crystal

a) Twinning: There shall be no electrical or optical twinning in the usable region.

b) Strain: There shall be no strain contained both inside and surface of seed crystal as well as in a grown quartz crystal.

c) Cracks and fractures: There shall be no cracks, chippings or fractures in the usable region.

d) Inclusion density: The specification is in accordance with the IEC 60758.

Size range | Qty per cm3 |

Grade (µm) | 10 to 30 | 30 to 70 | 70 to 100 | >100 |

Ia | 2 | 1 | 0 | 0 |

Ib | 3 | 2 | 1 | 1 |

I | 6 | 4 | 2 | 2 |

II | 9 | 5 | 4 | 3 |

III | 12 | 8 | 6 | 4 |

e) Infra-red quality indication: The specification is in accordance with the IEC 60758.

Grade | Max. α3585 | Estimated Q values (x 106) |

A | 0.015 | 3.8 |

A | 0.024 | 3 |

B | 0.05 | 2.4 |

C | 0.069 | 1.8 |

D | 0.1 | 1.4 |

f) Etch channel density: The specification is in accordance with the IEC 60758.

Grade | Max. number per cm3 |

1 | 10 |

2 | 30 |

3 | 100 |

4 | 300 |

5 | 600 |

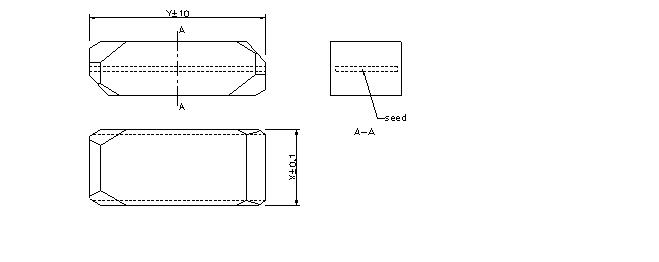

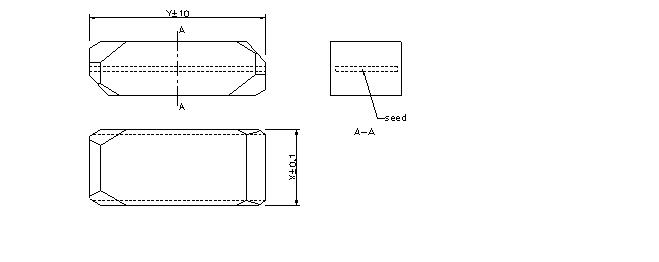

Specification for Lumbered Quartz Crystal

a) Angles:

i. Rotation angle of X-surface around Y-axis: 00°00’±15’

ii. Rotation angle of X-surface around Z-axis: 00°00’±15’

b) Dimensional tolerance:

i. Along X or Z axis:±0.1 mm

ii. Along Y axis:±10 mm

c) Surface roughness: as customized, lapped and polished are both available.