LiNbO3 wafers and Lithium Tantalate (LiTaO3, LT) are cornerstone materials in advanced optoelectronic and piezoelectric applications, prized for their unique optical, electrical, and mechanical properties. At OST Photonics, we specialize in providing high-quality LiNbO3 wafers and LT substrates tailored to meet the demands of cutting-edge technologies. Both materials excel in nonlinear optics, piezoelectric applications, and electro-optic devices, but they differ in key characteristics that influence their suitability for specific applications. This article offers a detailed comparison of Lithium Niobate (LiNbO3) and Lithium Tantalate, covering their crystal structures, optical and electrical properties, applications, and preparation methods, to guide tech enthusiasts and professionals in selecting the ideal material for their projects.

LiNbO3 crystal structure is characterized by a trigonal crystal system, belonging to the 3m point group and R3c space group, with lattice constants of a = b = 5.148 Å and c = 13.863 Å. This structure supports two primary variants: congruent LiNbO3 (CLN) and near-stoichiometric LiNbO3 (SLN). The non-centrosymmetric arrangement of atoms in LiNbO3 crystal enables its exceptional piezoelectric and nonlinear optical properties, making it a preferred choice for applications like surface acoustic wave (SAW) devices and optical modulators.

Lithium Tantalate shares a similar trigonal crystal system with an ilmenite-type ABO3 lattice, featuring lattice constants of a = 5.154 Å and c = 13.783 Å, and belongs to the C63vR3C point group. This structural similarity to LiNbO3 substrate underpins its comparable piezoelectric and ferroelectric properties, though subtle differences in lattice parameters contribute to its distinct performance in applications such as pyroelectric detectors and high-frequency filters.

Both LiNbO3 wafers and LT are renowned for their high quadratic nonlinear optical coefficients, enabling processes like frequency doubling, optical parametric oscillation, and sum-frequency generation. These properties make them indispensable in optical communication systems and laser technology. Their broad transparency windows—LiNbO3 from 0.4 to 2.9 µm and LT from 0.4 to 5.0 µm—enhance their utility across visible and infrared spectra.

The electro-optic coefficients of LiNbO3 substrate (no = 2.286, ne = 2.203 at 632.8 nm) and LT (no = 2.176, ne = 2.180 at 633 nm) allow precise modulation of refractive indices under electric fields, ideal for electro-optic modulators and switches. Their birefringence, resulting from dual refractive indices, supports polarization-dependent applications, enhancing their role in optical waveguides and photonic devices.

Lithium Niobate (LiNbO3) exhibits a unique photorefractive effect, where intense light exposure induces refractive index changes. This property is leveraged in holographic storage for applications like optical data processing and 3D memory. However, it can introduce challenges such as light-induced scattering, often mitigated through doping or thermal treatments. LT, in contrast, offers superior photorefractive resistance, making it a preferred choice for stable holographic storage with long-term data retention.

Both LiNbO3 crystal and LT are ferroelectric, capable of retaining polarization after an electric field is applied, due to their non-centrosymmetric structures. This makes them ideal for capacitors, sensors, and non-volatile memory devices. Their piezoelectric properties enable conversion between mechanical and electrical energy, supporting applications in resonators, transducers, and SAW filters. Compared to quartz, LiNbO3 wafers and LT offer higher electromechanical coupling coefficients, enabling high-frequency and wide-bandwidth devices critical for mobile and satellite communications.

The pyroelectric effect in LiNbO3 and LT allows them to generate electric charges in response to temperature changes, making them suitable for pyroelectric detectors. LT’s higher Curie temperature (610°C vs. LiNbO3’s 1140°C) and favorable dielectric constant enhance its performance in thermal sensing applications, such as infrared detectors.

LiNbO3 wafers and LT are widely used in SAW filters due to their high electromechanical coupling coefficients (10–12% for LiNbO3, 6–7% for LT). These filters offer low transmission loss, high reliability, and excellent frequency selectivity, making them essential for mobile communications, radar, and digital signal processing. LT’s zero-temperature coefficient at specific X-cut orientations allows precise control for high-frequency, wide-bandwidth filters, as detailed on OST Photonics.

Crystal oscillators utilizing LiNbO3 substrate or LT convert DC to AC at specific frequencies, leveraging their piezoelectric properties. While quartz is common, its lower coupling coefficient limits high-frequency performance. LT-based oscillators, as offered by OST Photonics, enable miniaturization and enhanced performance in high-frequency applications.

LT’s superior pyroelectric coefficient and Curie point make it a top choice for pyroelectric detectors, used in thermal imaging and environmental monitoring. LiNbO3 crystal is also employed, though LT’s performance often surpasses it in high-sensitivity applications.

In laser technology, LiNbO3 and LT serve as electro-optic Q-switches, compressing pulse widths and increasing peak power. LT’s high damage threshold and stability make it particularly effective for nanosecond pulsed lasers, as supported by OST Photonics’ high-quality substrates.

Lithium Niobate (LiNbO3) excels in holographic storage due to its photorefractive effect, enabling high-capacity, three-dimensional data storage. LT, with its enhanced photorefractive resistance, offers stable, long-term storage solutions, addressing challenges like volatility and slow response times in LiNbO3.

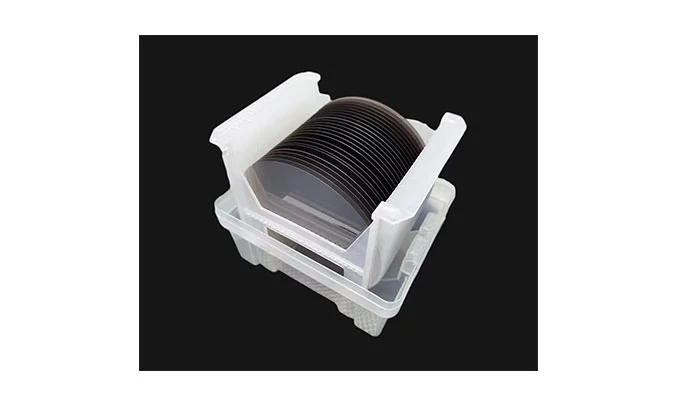

LiNbO3 wafers are typically grown using the Czochralski (crucible pulling) method for congruent compositions, with raw material ratios, pulling speed, and seed quality influencing crystal quality. Near-stoichiometric LiNbO3 (SLN) is produced via the double-crucible method or lithium diffusion, though challenges like equipment complexity and slow growth rates persist. OST Photonics employs optimized techniques to ensure high optical homogeneity and cost-effective production.

LT crystals are grown using the Czochralski method with a stoichiometric ratio of tantalum pentoxide and lithium carbonate. Near-stoichiometric LT is prepared via methods like the double-crucible or flux pulling techniques, each with trade-offs in complexity and homogeneity. OST Photonics ensures high-quality LT wafers through advanced processing, minimizing defects and ensuring consistency.

Property | LiNbO3 Wafers | Lithium Tantalate |

|---|---|---|

Melting Point | 1250°C | 1650°C |

Curie Temperature | 1140°C | 610°C |

Density | 4.64 g/cm³ | 7.45 g/cm³ |

Spectral Transmission | 0.4–2.9 µm | 0.4–5.0 µm |

Photorefractive Resistance | Moderate | High (2 orders higher) |

LiNbO3 wafers are ideal for applications requiring strong photorefractive effects, such as holographic storage, while LT is preferred for stable, high-frequency applications like SAW filters and pyroelectric detectors. OST Photonics offers both materials, customized to meet specific project needs.

Lithium Niobate (LiNbO3) and Lithium Tantalate are pivotal materials in optoelectronic and piezoelectric technologies, each offering unique advantages. LiNbO3 wafers excel in holographic storage and nonlinear optics, while LT provides superior photorefractive resistance and thermal stability. At OST Photonics, we provide high-quality LiNbO3 substrates and LT wafers, tailored to your application needs. Contact our specialists for expert guidance on selecting the right material for your project.