Gallium arsenide (GaAs) is a compound synthesized by two elements of gallium and arsenic. It is an important group IIIA and group VA compound semiconductor material. And it can be used to make microwave integrated circuits, infrared light-emitting diodes, semiconductor lasers and solar cells. GaAs is often used as the base material for the epitaxial growth of III-V semiconductors, including indium gallium arsenide, aluminum gallium arsenide, and so on.

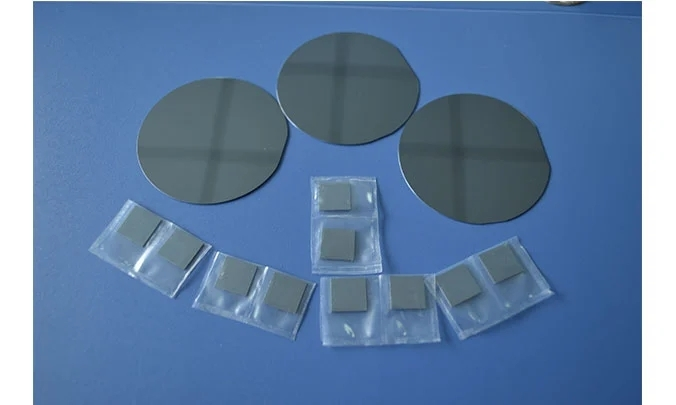

OST Photonics offers high quality GaAs substrates for researchers and industries. There are five types of GaAs materials for you to choose from: semi-insulating GaAs (undoped), N-type GaAs (Si doped), semi-insulating GaAs (Cr doped), N-type GaAs (Te doped) and P-type GaAs (Zn doped). Crystal size and thickness can be customized according to your requirements.