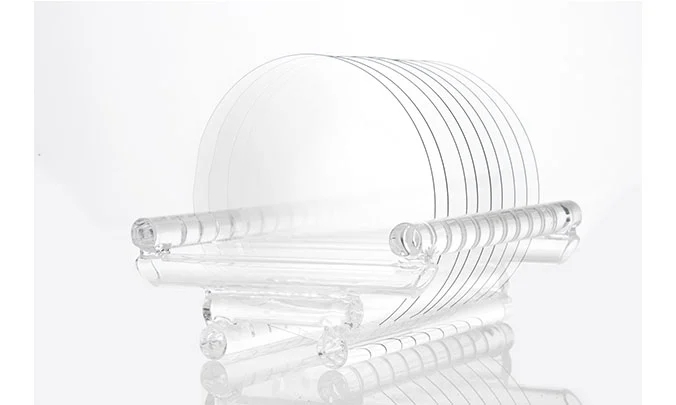

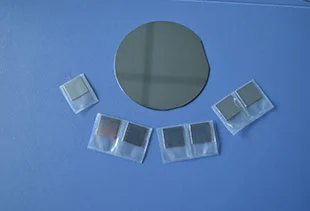

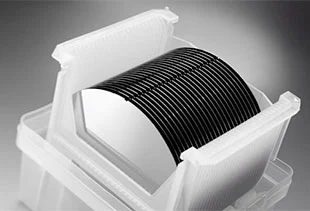

OST Photonics offer 4” and 6” SiC wafers for semiconductor industry. There are two conduct types of SiC materials for you to choose from: N-type SiC (Nitrogen doped) and high purity semi-insulating SiC (undoped). High purity semi-insulating SiC wafers is mainly used in 5G communication applications. It has the advantages of improving the radio frequency range, ultra-long distance recognition, anti-interference, high-speed and large-capacity information transmission, and is regarded as the most ideal material for making microwave power devices. N-type SiC wafer is mainly used in new energy vehicles, high voltage transmission and transformation stations, white goods, high-speed trains, motors, photovoltaic inverter, pulse power supply and other fields, it has the advantages of reducing equipment energy loss, improving equipment reliability, reducing equipment volume, improving equipment performance and so on, it has irreplaceable advantages in the production of power electronic devices. In addition, SiC ingots and customized SiC substrates are also available upon requests.